The Evolution of Chinese Manufacturing Excellence

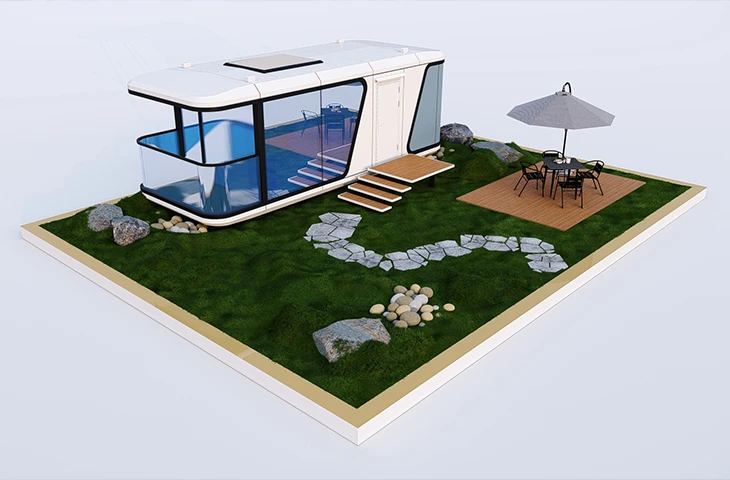

China’s transformation into the world’s capsule house production capital represents one of modern manufacturing’s most remarkable success stories. Over the past decade, Chinese manufacturers have progressed from basic prefabrication to sophisticated engineering that sets global benchmarks. At PodVoyager, we embody this evolution through our vertically integrated manufacturing campus in Shandong, where precision engineering meets artisanal craftsmanship. Unlike resellers who simply source from anonymous factories, we’ve invested in developing proprietary production systems that merge German-level precision with Japanese efficiency principles. This commitment to manufacturing excellence positions PodVoyager at the forefront of China’s quality revolution in modular construction.

Our 35,000-square-meter facility operates as an ecosystem of innovation, where material scientists collaborate with structural engineers to solve challenges that conventional construction cannot address. The PodVoyager difference begins at the molecular level – we’ve reformulated composite panel formulations seventeen times to achieve the optimal balance between thermal performance, structural integrity, and environmental sustainability. This relentless refinement process continues daily, with each production batch incorporating incremental improvements that collectively represent significant advances in capsule house technology. When you choose a PodVoyager capsule, you’re not just purchasing a structure; you’re acquiring the cumulative intelligence of thousands of hours of research and real-world performance data.

The Tangible Advantages of Factory-Direct Sourcing

Purchasing directly from a manufacturing brand like PodVoyager eliminates the hidden costs and quality uncertainties that plague the capsule house industry. While brokers and resellers add unnecessary markup layers, our factory-direct model ensures every dollar delivers measurable engineering value. More importantly, our vertical integration provides quality control impossible through outsourced production. Within our climate-controlled assembly bays, skilled technicians implement a 49-point verification protocol that examines everything from weld integrity to microscopic sealant application. This meticulous attention to detail results in assembly tolerances measured in millimeters rather than centimeters – a precision difference that translates directly to superior weather resistance and long-term durability.

The manufacturing transparency we offer clients remains unprecedented in the industry. Through our client portal, buyers can monitor their capsule’s progress from raw material staging to final quality assurance checks. This visibility extends to material certifications, with complete traceability for every composite panel, window unit, and hardware component. For commercial clients, we facilitate third-party inspections at critical production milestones, providing documented verification of quality standards. This radical transparency stems from our confidence in manufacturing processes refined through supplying capsules to demanding environments from Arctic research stations to tropical resorts.

Engineering for Global Realities

Chinese capsule houses often face unfair stereotypes about climate limitations. At PodVoyager, we’ve engineered these misconceptions into obsolescence through purpose-built solutions for Earth’s most challenging environments.

This specialized engineering extends to regulatory compliance – a frequent pain point for international buyers. Our in-house certification team maintains current knowledge of 37 regional building codes, from California seismic requirements to Nordic fire safety standards. For each project, we provide a comprehensive compliance dossier that simplifies local permitting processes. This documentation includes structural calculations validated by internationally recognized engineering firms, material safety certifications, and factory production control records required by stringent European standards. This turnkey compliance support has proven invaluable for developers navigating complex regulatory landscapes in multiple jurisdictions simultaneously.

The PodVoyager Customization Advantage

Conventional wisdom suggests customization compromises quality in modular construction. We’ve disproven this notion through our flexible manufacturing system that accommodates bespoke engineering without sacrificing structural integrity. Unlike brands offering superficial finish options, PodVoyager enables meaningful architectural modifications through our parametric design platform. Clients can adjust dimensions within engineering parameters, reconfigure interior layouts, or specify specialized features like medical-grade ventilation systems – all while maintaining our core performance guarantees. This flexibility recently enabled a Swiss client to create accessible capsule housing meeting strict disability standards, while a Malaysian resort developer integrated traditional woodcraft into contemporary modular designs.

Our customization extends beyond physical structures to encompass comprehensive technical integration. The PodVoyager SmartCore system provides pre-engineered pathways for renewable energy systems, home automation networks, and satellite communications equipment. This forward-looking approach ensures today’s capsule house remains technologically relevant for decades, accommodating innovations not yet imagined. For commercial applications, we implement industrial IoT systems that monitor structural health, environmental conditions, and maintenance requirements – transforming passive structures into data-rich assets. Explore our design philosophy to understand how we balance customization with engineering rigor.

Beyond the Product: The PodVoyager Ecosystem

Choosing PodVoyager means accessing support infrastructure that extends far beyond capsule delivery:

Logistics Mastery

Our shipping protocols optimize container space utilization while ensuring components arrive undamaged. For remote locations, we’ve developed helicopter-transportable modules and desert-optimized packaging.

Global Technical Network

We maintain partnerships with certified installers across 23 countries, ensuring proper assembly regardless of location. Clients receive detailed video documentation of their specific model’s installation process, supplemented by video support during critical stages.

Continuous Innovation Program

Owners gain access to upgrade pathways as new technologies emerge. Recent innovations include phase-change temperature regulation systems and self-repairing surface coatings developed through our materials research division.

Resilience Certification

Commercial clients receive annual structural integrity assessments and environmental performance reports, documenting maintenance savings and sustainability metrics for ESG reporting.

Why Global Professionals Choose PodVoyager

Architects consistently select our capsules for projects demanding precision because we provide:

- BIM models with certified structural data

- Material transparency documentation

- Custom component integration services

- Site-specific engineering analysis

Developers favor PodVoyager for large-scale deployments due to:

- Batch consistency across multiple units

- Predictable production timelines

- Integrated compliance packages

- Volume optimization without minimums

Government agencies trust our solutions for critical applications because we deliver:

- Documented performance validation

- Emergency response configurations

- Maintenance simplicity in remote locations

- Lifecycle cost predictability

Experience the PodVoyager Difference

Chinese capsule houses represent the convergence of manufacturing scale, engineering talent, and technological innovation. At PodVoyager, we’ve harnessed these advantages through disciplined quality systems that transform theoretical potential into consistent real-world performance. Our factory-direct approach eliminates compromises while providing unprecedented transparency throughout the design, manufacturing, and installation process.

We invite you to move beyond commodity comparisons and experience engineering excellence tailored to your requirements. Contact our technical team for:

- Climate-specific performance projections

- Customization feasibility assessments

- Site-specific configuration advice

- Compliance pathway analysis

- Total cost of ownership modeling

Visit PodVoyager to access our technical resource library featuring detailed engineering white papers, case studies from extreme environments, and manufacturing process documentation. For personalized consultation, schedule a factory virtual tour with our engineering team. Discover why global buyers choose PodVoyager when quality, compliance, and long-term performance matter most in capsule house selection.